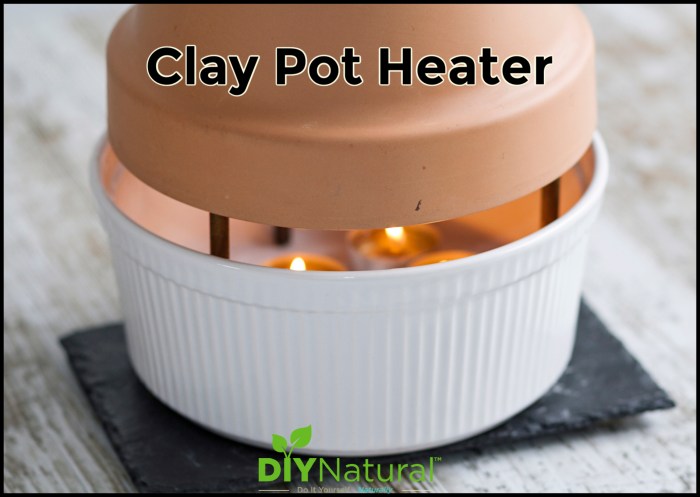

DIY terracotta pot heater sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset.

Imagine a cozy evening by the fireplace, but instead of a roaring fire, you have a gentle, warm glow emanating from a terracotta pot. This is the essence of DIY terracotta pot heaters, a fascinating and surprisingly simple way to create a warm and inviting atmosphere in your home. These heaters are not only efficient and economical, but also offer a unique charm that adds a touch of rustic elegance to any space. This guide will delve into the world of DIY terracotta pot heaters, exploring the materials, construction process, safety considerations, and various design options.

Materials and Tools

Building a terracotta pot heater is a fun and rewarding project, and you don’t need a lot of fancy materials. You can likely find most of what you need around the house or at your local hardware store.

This section Artikels the essential materials needed for building a terracotta pot heater, provides tips for gathering and preparing them, and describes the tools necessary for the construction process.

Materials

The following materials are essential for building a terracotta pot heater:

- Terracotta pot: Choose a pot that is large enough to accommodate the heat source and provide adequate space for airflow. A pot with a wide opening is ideal for efficient heat distribution.

- Heat source: A candle or a small electric heater can be used as a heat source. Ensure the heat source is compatible with the size and material of the terracotta pot.

- Heat-resistant material: This material will be used to line the bottom of the pot and protect it from the heat source. You can use a heat-resistant mat, ceramic tiles, or even a layer of sand.

- Aluminum foil: This will be used to reflect heat back into the room. You can use a roll of aluminum foil and cut it to fit the size of the pot.

- Wire mesh: This will be used to create a platform for the heat source. You can use a piece of wire mesh that is slightly smaller than the opening of the pot.

- Adhesive: This will be used to secure the wire mesh to the terracotta pot. A heat-resistant adhesive is recommended for long-lasting results.

- Decorative elements (optional): You can add decorative elements to your terracotta pot heater, such as paint, fabric, or beads. These will personalize your heater and add a touch of style to your space.

Tools

You will need the following tools for building your terracotta pot heater:

- Scissors: Used for cutting the aluminum foil and wire mesh to size.

- Measuring tape: Used to measure the dimensions of the pot and the heat source.

- Pliers: Used to bend the wire mesh and secure it to the pot.

- Safety glasses: Used to protect your eyes from debris during construction.

Construction Process

This section provides a step-by-step guide on building the terracotta pot heater. The construction process involves assembling the heater’s components, ensuring proper insulation, and connecting the heating element.

Preparing the Terracotta Pot

Before assembling the heater, it’s crucial to prepare the terracotta pot. This involves cleaning the pot, drilling holes for ventilation, and creating a secure base for the heating element.

- Clean the terracotta pot thoroughly with soap and water, removing any dirt or debris. This ensures that the pot is free of any contaminants that could affect the heater’s performance.

- Using a drill with a suitable bit, drill several ventilation holes around the pot’s sides. These holes allow for air circulation, preventing overheating and ensuring proper heat distribution. The number and size of the holes can be adjusted based on the size of the pot and the desired heating capacity.

- Create a secure base for the heating element by attaching a heat-resistant plate or a piece of metal mesh to the bottom of the pot. This prevents direct contact between the heating element and the terracotta, minimizing the risk of damage and ensuring proper heat transfer.

Installing the Heating Element

The heating element is the core component of the terracotta pot heater. It converts electrical energy into heat, providing warmth to the surrounding area. Proper installation of the heating element is crucial for efficient and safe operation.

- Securely attach the heating element to the base of the pot. Ensure that the heating element is positioned in a way that allows for proper heat distribution within the pot. The heating element should be centered and evenly spaced from the pot’s sides.

- Connect the heating element to the power source using appropriate wiring. Ensure that the wiring is properly insulated and securely connected to both the heating element and the power source. Follow all electrical safety guidelines and regulations when connecting the heating element.

- To prevent overheating and potential damage, consider installing a thermostat to control the heater’s temperature. A thermostat automatically adjusts the heating element’s power output based on the desired temperature setting, ensuring a consistent and safe heating experience.

Adding Insulation

Insulation plays a crucial role in maintaining heat and improving the efficiency of the terracotta pot heater. By reducing heat loss, insulation ensures that the heater effectively warms the surrounding area.

- Choose an appropriate insulation material that can withstand high temperatures and is compatible with the terracotta pot. Some suitable insulation materials include ceramic fiber insulation, mineral wool, or perlite. These materials offer excellent thermal resistance and are safe for use in high-temperature applications.

- Apply the insulation material around the heating element and the pot’s sides. Ensure that the insulation is evenly distributed and securely attached to prevent gaps or air pockets. Proper insulation minimizes heat loss and maximizes the heater’s efficiency.

- Cover the insulation with a heat-resistant material such as a metal sheet or a ceramic coating. This protects the insulation from damage and ensures a clean and aesthetically pleasing finish.

Final Touches

After completing the construction process, it’s important to add some finishing touches to enhance the heater’s functionality and appearance.

- Create a secure and aesthetically pleasing enclosure for the heater. This can be achieved by building a wooden frame or using a metal sheet to enclose the pot. The enclosure should provide adequate ventilation and be designed to withstand the heat generated by the heater.

- Consider adding a decorative element to the heater. This could be a simple paint job, a decorative tile, or a personalized design. Adding a decorative element enhances the heater’s visual appeal and makes it a unique and functional addition to your home.

- Test the heater thoroughly before using it. Ensure that the heating element is working properly, the insulation is effective, and the enclosure is safe. It’s crucial to operate the heater in a well-ventilated area and follow all safety guidelines to prevent accidents or damage.

Safety Considerations: Diy Terracotta Pot Heater

While building your own terracotta pot heater can be a fun and rewarding project, it’s crucial to prioritize safety throughout the process and during use. DIY heaters, like any electrical appliance, pose potential fire hazards if not handled correctly. Understanding these risks and implementing proper safety measures is essential to prevent accidents and ensure a safe heating experience.

Fire Hazards and Mitigation

Terracotta pot heaters utilize heat generated from a heating element, which can be a potential fire hazard if not properly insulated and protected. Here are some key fire hazards to consider and how to mitigate them:

- Overheating: The heating element can overheat if it’s not properly ventilated or if the pot is placed on a flammable surface. This can lead to a fire.

- Electrical Short Circuits: Faulty wiring or damage to the heating element can cause electrical short circuits, potentially leading to sparks and fire.

- Combustible Materials: Placing the heater near flammable materials, such as curtains, furniture, or paper, increases the risk of a fire.

To mitigate these risks, follow these recommendations:

- Use a Thermostat: A thermostat helps regulate the temperature of the heater, preventing overheating.

- Proper Ventilation: Ensure the heater has adequate ventilation to prevent the buildup of heat and avoid overheating.

- Safe Placement: Place the heater on a non-flammable surface, away from flammable materials.

- Regular Inspection: Regularly inspect the wiring and heating element for any damage or wear and tear.

Safe Operation and Maintenance

Safe operation and maintenance are crucial to ensure the longevity and safety of your DIY terracotta pot heater. Here are some essential tips:

- Never leave the heater unattended: Always supervise the heater when it’s in use, especially when children or pets are around.

- Unplug the heater when not in use: Disconnect the heater from the power source when not in use to prevent potential accidents.

- Regular Cleaning: Regularly clean the heater to remove dust and debris, which can obstruct airflow and lead to overheating.

- Use a GFCI outlet: A Ground Fault Circuit Interrupter (GFCI) outlet can help prevent electrical shocks by quickly cutting off power in case of a fault.

It’s important to remember that DIY heaters should never be used as a primary heat source. They are intended for supplemental heating only.

Alternative Designs

The basic terracotta pot heater design is a simple and effective way to provide supplemental heat, but there are several variations and modifications that can be made to improve its performance and aesthetics. These modifications can include using different materials, incorporating additional features, and optimizing the design for specific applications.

Here are some alternative designs and their respective pros and cons:

Different Materials

While terracotta is a popular choice for its porous nature, other materials can be used to construct a DIY heater.

A DIY terracotta pot heater is a great way to add a touch of warmth and rustic charm to your home. If you’re looking for more inspiration for upcycling projects, check out some amazing pallet DIY projects that can transform these humble materials into stunning furniture and decor. Once you’ve mastered those, you can return to your terracotta pot heater project and create a truly unique and functional piece.

- Ceramic Pots: Similar to terracotta, ceramic pots offer good heat retention and can be used to build a heater. However, they may be less porous than terracotta, which could affect the efficiency of heat transfer.

- Stoneware Pots: Stoneware pots are known for their durability and resistance to cracking. They can be used to build a heater, but they may not be as porous as terracotta or ceramic, which could affect the efficiency of heat transfer.

- Metal Containers: Metal containers, such as old cans or buckets, can also be used to build a heater. They offer better heat transfer than terracotta or ceramic, but they may require more insulation to prevent overheating.

Additional Features

Adding features to the basic design can enhance the heater’s functionality and aesthetics.

- Thermostat: A thermostat can be added to the heater to automatically regulate the temperature. This can help prevent overheating and ensure optimal efficiency.

- Fan: A small fan can be incorporated into the design to circulate the warm air. This can improve the distribution of heat and create a more comfortable environment.

- Decorative Elements: The heater can be decorated with paint, stencils, or other decorative elements to enhance its aesthetic appeal.

Innovative Designs

Some innovative DIY terracotta pot heater designs have been developed, offering unique functionalities and benefits.

- Terracotta Pot Heater with Built-in Fan: This design integrates a small fan within the terracotta pot to circulate the warm air more effectively. This can improve the distribution of heat and create a more comfortable environment.

- Terracotta Pot Heater with Adjustable Temperature Control: This design incorporates a thermostat and a control knob to adjust the temperature of the heater. This allows for more precise temperature regulation and ensures optimal efficiency.

- Terracotta Pot Heater with Multiple Heat Sources: This design utilizes multiple heat sources, such as candles or tea lights, to generate more heat. This can be useful for larger spaces or areas that require more warmth.

Troubleshooting and Repair

Even the most carefully constructed DIY terracotta pot heater can experience issues. Understanding common problems and how to address them is crucial for maintaining your heater’s functionality and extending its lifespan. This section will guide you through troubleshooting common problems and provide practical solutions for repair and maintenance.

Troubleshooting Common Issues, Diy terracotta pot heater

Troubleshooting a terracotta pot heater involves systematically identifying the root cause of the problem and implementing appropriate solutions. Here are some common issues and their potential causes:

- No Heat Output: This could be due to a faulty heating element, a broken thermostat, or a power supply issue.

- Uneven Heat Distribution: If the heat is concentrated in specific areas of the pot, it might be because of an unevenly placed heating element or a poorly insulated pot.

- Excessive Heat: A malfunctioning thermostat or an overly powerful heating element can lead to excessive heat, potentially posing a safety hazard.

- Cracked Pot: The terracotta pot might crack due to thermal shock, especially if exposed to sudden temperature changes.

- Electrical Problems: Loose connections, damaged wiring, or a faulty power cord can cause electrical issues.

Repairing and Maintaining the Heater

Addressing issues with your terracotta pot heater often involves simple repairs and regular maintenance.

- Replacing the Heating Element: If the heating element is faulty, you’ll need to replace it with a compatible one. Disconnect the heater from the power source before attempting any repairs.

- Adjusting the Thermostat: A malfunctioning thermostat can be adjusted or replaced to ensure proper temperature control.

- Checking Wiring and Connections: Inspect the wiring and connections for loose or damaged components. Secure loose connections and replace damaged wires.

- Insulating the Pot: Applying a layer of insulation, such as ceramic fiber blanket, can help prevent heat loss and ensure even heat distribution.

- Preventing Thermal Shock: Avoid sudden temperature changes by gradually warming up the pot and allowing it to cool down slowly.

- Regular Cleaning: Clean the heater regularly to remove dust and debris that can hinder its performance and potentially cause safety hazards.

Addressing Specific Issues

For more specific issues, you can consult online resources, forums, or seek advice from an experienced electrician or a professional specializing in heating systems.

Cost Considerations

Building a DIY terracotta pot heater can be a budget-friendly way to supplement your heating needs. The cost of materials is generally low, and you can often find many of the necessary items around your home or at a local hardware store. However, it’s essential to compare the costs of DIY heaters with commercially available options to determine the most cost-effective approach.

Comparison with Commercially Available Options

The cost of DIY terracotta pot heaters is typically significantly lower than commercially available options. This is primarily because you are only paying for the materials, not the labor and manufacturing costs associated with pre-built heaters. However, commercially available heaters often offer features that DIY heaters may not, such as safety features, automatic temperature control, and a more polished aesthetic.

- DIY terracotta pot heater: The cost of a DIY terracotta pot heater can range from $10 to $30, depending on the materials used and the size of the pot.

- Commercially available heaters: Commercially available heaters can range in price from $30 to $200 or more, depending on the size, features, and brand.

Long-Term Cost Savings

While the initial cost of a DIY terracotta pot heater is lower, the long-term cost savings can be significant. This is because DIY heaters typically use less energy than commercially available options, leading to lower electricity bills.

- Energy efficiency: DIY terracotta pot heaters are generally more energy-efficient than commercially available heaters because they utilize radiant heat, which is more efficient at warming spaces than forced air heating.

- Lower operating costs: The lower energy consumption of DIY heaters translates to lower operating costs, leading to long-term savings on electricity bills.

For example, a 1000-watt electric heater running for 10 hours per day at a rate of $0.15 per kilowatt-hour would cost approximately $15 per day to operate. In contrast, a DIY terracotta pot heater with similar heating capacity might only consume 500 watts, resulting in a daily operating cost of $7.50.

Building a DIY terracotta pot heater is a rewarding project that combines creativity, practicality, and a touch of DIY magic. From the initial planning stages to the final assembly, this guide has provided you with the essential knowledge and techniques to create your own cozy and efficient heater. Remember to prioritize safety and always double-check your work before plugging in your heater. By following the guidelines and tips Artikeld in this guide, you can enjoy the warmth and ambiance of a DIY terracotta pot heater for years to come.